Call us: 9:00am - 6:00pm

+91-22-68520000

E-mail us

kushal@kushalmetal.net

Introduction

M-42 super high speed steel is a premium cobalt high speed steel with a chemical composition designed for high hardness and superior hot hardness. These properties make the steel an excellent choice for machining high-strength and pre-hardened steels, high-hardness alloys, and the difficult-to-machine, nonferrous super alloys used in the aerospace, oil, and power generation industries.

M-42 exhibits excellent wear resistance by virtue of high heat-treated hardness (68 to 70 HRC), and the high cobalt content imparts the hot hardness. As such, the cutting edges on tools made from M42 super high speed steel stay sharp and hard in heavy-duty and high-production cutting applications.

Smelting method : 15T Intermediate frequency furnace (EAF+LF+VD+ESR)

Main Characteristics : High steel hardness, reaching 68HRC after quenching and tempering, favorable hot hardening, capable of manufacturing various complicated tools with high precision.

Major Applications : Capable of manufacturing abrasion resistant and impact resistant tools for various types of powerful cutting.

High-level trimming dies, screw dies, formed punches of complicated shapes requiring tenacity, etc.

Scrapers, hobs, drilling, bits, etc.

Cold forging molds.

Chemical Composition : (%)

| C | Si | Mn | W | Cr |

| 1.08 | 0.3 | 0.3 | 1.45 | 3.95 |

| Mo | V | Co | P | S |

| 9.40 | 1.15 | 7.85 | ≤0.020 | ≤0.001 |

| O (ppm) | N (ppm) | H (ppm) |

| ≤1.08 | ≤100 | ≤2.5 |

Grades Equivalent :

STANDARD |

BRAZIL |

AUSTRIA |

SLOVANIA |

1.3247 |

VKM42 |

S500 |

BRCMO2 |

JIS |

CZECH REP. |

CHINA |

AMERICAN |

SKH59 |

MAXEX

42 |

W2Mo9Cr4VCo8 |

M-42 |

Physical Property : (%)

| Room temperature density (kg/m³) | Specific heat of room temperature (J/Kg.K) | 200°C thermal conductivity (W/m.K) |

| 8.01 | 460 | 19.00 |

| Elastic mouldsus (N/nm²) | Linear Expensivity (x10-6K) 20 ~ 200°C

20 ~ 400°C

|

| 220,000 |

10.8

11.6

|

Ultrasonic flaw detection :

As per SEP1921: E/e or customer requirements.

Purity :

| Class A | Class B | ||

| Fine | Coarse | Fine | Coarse |

| 0.5 | 0.5 | 0.5 | 0.5 |

| Class C | Class D | ||

| Fine | Coarse | Fine | Coarse |

| 0.5 | 0.5 | 0.5 | 0.5 |

Delivery State :

(1) Delivery under balling annealing state, delivery hardness ≤269HB;

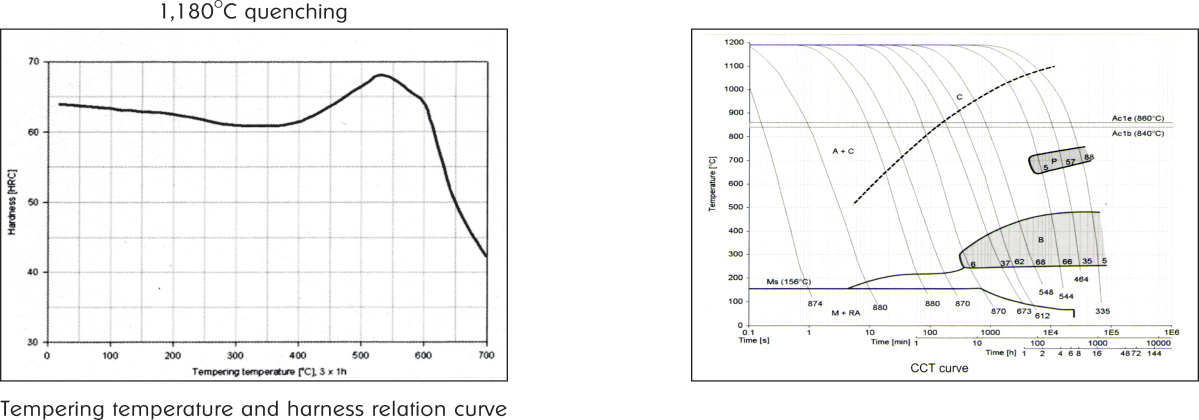

Thermal Treatment :

| Softening annealing | Quenching |

| Heating to 850°C for heat insulation; cooling to 550°C slowly and then removing from the furnace. | 1,175~1,180 quenching; high speed gas quenching or hot oil cooling |

| Tempering |

| Tempering temperature 540~570°C, at least three times of tempering. |

Get in Touch

Please Feel Free to Contact Us

Call us on

+91-22-68520000

Email us

kushal@kushalmetal.net