Call us: 9:00am - 6:00pm

+91-22-68520000

E-mail us

kushal@kushalmetal.net

Introduction

DIN 1.2738 steel is one kind of plastic mold steel especially for big steel mold parts, it is equivalent to AISI P20+Ni tool steel.

Smelting method : EAF+LF+VD+ESR

Main Characteristics : If futures excellent hardening penetration, good workability, polishing and photoengraving properties, This steel is used for plastic moulds of medium and big size. It can be subject to a nitriding treatment to improve its wear resistance.

Major Applications : Injections and thermoplastic extrusion moulds, rubber moulds, moulds carrier frames, container.

Chemical Composition : (%)

| C | Si | Mn | Cr |

| 0.35-0.45 | 0.20-0.40 | 1.30-1.60 | 1.80-2.10 |

| Mo | Ni | P | S |

| 0.15-0.25 | 0.90-1.20 | ≤0.030 | ≤0.030 |

Comparable Standards : (%)

| UNI | W.Nr | DIN |

| - | 1.2738 | 40Cr/MnNiMo8-6-4 |

| AFNOR | AISI/SAE | BS |

| ~40 CMND8 | ~P20 + Ni | ~P20 + Ni |

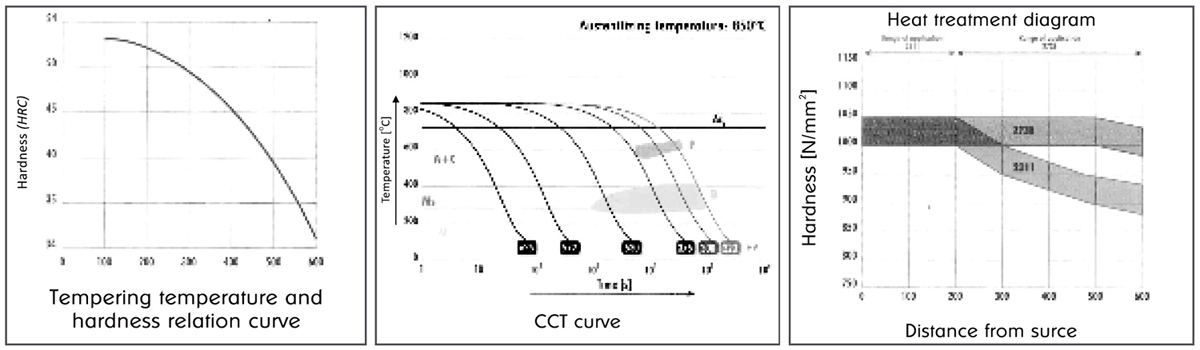

Critical Points :

| Ac 1 | 710°C |

| Ms | 290°C |

Supply Conditions : Hardened and Tempered Normal HP 280-320 & 380-400

Heat Treatments :

Annealing :

Heat to 710-740℃, with hold at minimum rate for 3 hours.

Slow furnace cooling to 600℃.

Stress relieving :

To be carried out after machining and before the final heat treatment

Heating to 530-580℃ for 2 hours.

Hardening :

Preheating to 500-550℃

Austenitizing at 840-880℃

Oil or thermal bath cooling at 200-230℃, then oil cooling according to the steel shape size

Quenched hardness 52-54 HRC

Tempering :

To be carried out after the hardening and when the steel is at 60-80℃, at 500-600℃ according to the required hardness and with permanance for atleast 2 Hr.

Cooling in air

Get in Touch

Please Feel Free to Contact Us

Call us on

+91-22-68520000

Email us

kushal@kushalmetal.net