Call us: 9:00am - 6:00pm

+91-22-68520000

E-mail us

kushal@kushalmetal.net

Welcome to your premier source for high-quality High Speed Steel (HSS). Our commitment is to provide exceptional HSS products that cater to diverse industrial applications, ensuring superior performance and reliability.

Standard high-speed steel grade. High toughness and good cutting power owing to its well-balanced alloy composition; thus suitable for a wide variety of applications. It is used to manufacture knives, thread cutting & twist drills, sendizimer rolls, taps, broaches & milling tools, reamers, metal/circular saws, wood working & cold forming tools.

It is one of the W-Mo Co hss grade with good cutting character. The res hardness, hot hardness and wearing resistance are all better than W6M05Cr4V2.

Milling Cutters, Twist Drills, Taps, Broaching Tools, Cold Work Tools.

Turning and Milling tools for roughing and finishing works, wood working tools, highly stressed cold works tools, tool bits.

It is an economical low alloy high-speed steel with good red hardness, good toughness and thermal plasticity. It is generally used soft and moderate intensity metal.

TGM2A is a special grade containing low percentage of carbon to increase toughness & added Niobium to find crystal grains of steel to obtain high strength & toughness specially suited for taps & tabs of thread tools.

As a high speed Steel Supplier, we provide a wide range of premium materials suited for various industries.

Chemical Analysis

Germany DIN |

USA AISI |

CHEMICAL ANALYSIS (typical values) % Min-Max |

Delivery Conditions |

Applications |

||||||||||

Grade |

C |

S |

P |

Si |

Mn |

Cr |

Mo |

V |

W |

Co |

Heat Treatment |

Hardness

(HB) |

||

0.86- 0.94 |

<0.030 |

<0.030 |

0.20- 0.45 |

0.20- 0.40 |

3.75- 4.50 |

4.50- 5.50 |

1.60- 2.20 |

5.90- 6.75 |

- |

Annealed |

<255 |

Standard high-speed steel grade. High toughness and good

cutting power owing to its well-balanced alloy composition; thus

suitable for a wide variety to applications. It is used to manufacture knives, thread cutting & twist drills, sendizimer rolls, taps, broaches & milling tools, reamers, metal/circular saws, wood working & cold forming tools. |

||

0.88- 0.95 |

<0.030 |

<0.030 |

0.20- 0.40 |

0.20- 0.45 |

3.80- 4.50 |

4.75- 5.50 |

1.75- 2.15 |

6.00- 6.75 |

4.55- 5.50 |

Annealed |

<277 |

It is one of the W-Mo Co hss grade with good cutting character.

The res hardness, hot hardness and wearing resistance are all

better than W6M05Cr4V2. |

||

1.05- 1.15 |

– |

– |

0.15- 0.65 |

0.15- 0.40 |

3.50- 4.25 |

9.00- 10.00 |

0.95- 1.35 |

1.15- 1.85 |

7.75- 8.75 |

Annealed |

<285 |

Milling Cutters, Twist Drills, Taps, Broaching Tools,

Cold Work Tools. |

||

1.3207 |

T-42 |

1.25- 1.40 |

– |

– |

0.20- 0.30 |

0.20- 0.30 |

3.80- 4.30 |

3.20- 3.80 |

3.00- 3.50 |

9.00- 9.80 |

9.80- 10.80 |

Annealed |

<285 |

Turning and Milling tools for roughing and finishing works, wood

working tools highly stressed cold works tools, tool bits. |

0.90- 0.95 |

≤0.020 |

≤0.030 |

0.80- 1.20 |

0.25- 0.40 |

4.00- 4.50 |

2.00- 2.50 |

1.00- 1.30 |

4.00- 4.50 |

- |

Annealed |

<255 |

It is an economical low alloy high-speed steel with good red

hardness, good toughness and thermal plasticity. It is generally used soft and moderate intensity metal. |

||

0.83- 0.93 |

≤0.020 |

≤0.030 |

0.70- 1.20 |

0.20- 0.40 |

4.00- 4.50 |

3.00- 3.50 |

1.20- 1.80 |

4.00- 4.50 |

- |

Annealed |

<255 |

|||

TG M2A Special grade for taps |

0.83- 0.85 |

MAX 0.010 |

MAX 0.030 |

0.30- 0.40 |

0.20- 0.40 |

3.90- 4.20 |

4.80- 4.85 |

1.80- 1.90 |

6.00- 6.20 |

Nb 0.10- 0.12 |

Annealed |

<255 |

TGM2A is a special grade containing low percentage of carbon to

increase toughness & added Niobium to find crystal grains of

steel to obtain high strength & toughness specially suited for taps & tabs of thread tools. |

|

Grade Equivalent

DIN STANDARD |

BRAZIL |

AUSTRIA |

SLOVANIA |

JIS |

CZECH REP. |

CHINA |

AMERICAN |

VWM2 |

S600 |

BRM2 |

SKH51 |

MAX SP MO5S |

W6Mo5Cr4V2 |

M-2 |

|

VK5E |

S705 |

BRCMO |

SKH55 |

MAX SP 75D |

W6Mo5CrV2Co5 |

M-35 |

|

VKM42 |

S500 |

BRCMO2 |

SKH59 |

MAXEX 42 |

W2Mo9Cr4VCo8 |

M-42 |

|

1.3207 |

VK10E |

S700 |

BRU |

SKH57 |

RADECO M10 |

– |

T-42 |

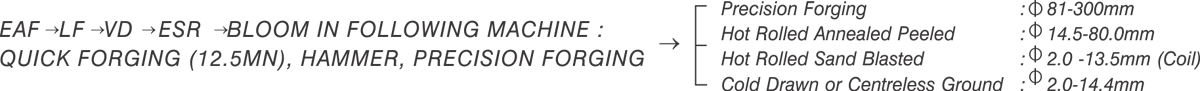

Production Process :

| Under Annealed Condition : | Reduction Ratio : | Delivery Status : |

| Hardness : HB205-255 | As 1:4 or 1:5 | As Cold drawn / Hot rolled / forged, in annealed condition |

Sizes of Round Bars :

Cold Drawn/Ground Bar |

Hot Rolled Annealed Peeled Bar |

Forged Anealed Turned Bar |

Coil |

Φ 2.0 - 14.4mm |

Φ 14.5 - 80.0mm |

Φ 81.0 - 300.0mm |

Φ 2.0 - 13.5mm |

Sizes of Hot Rolled Flat Bars/Sand Blasted Machined Straight :

Thickness |

Width |

4mm - 205mm |

4mm - 810mm |

Sizes of Square Bars :

| 4mm - 27mm |

Sizes of Sheets :

| 0.5mm - 12mm |

Get in Touch

Please Feel Free to Contact Us

Call us on

+91-22-68520000

Email us

kushal@kushalmetal.net